About us

Welcome to our factory!

Zhangqiu Xindong Casting Machinery Co., Ltd. is located in Liujia Industrial Park, Zhangqiu City, Jinan. It is a professional enterprise integrating gravity casting, machine treatment and mold design and manufacturing. It was founded in March 2003, passed IATF 16949 national quality management system certification in May 2009, and passed ISO9001 certification, ISO14001 certification and iso45001 certification in 2019 It has been awarded as the "three level enterprise of safety production standardization" with a working capital of US $7000000, covering an area of 100000 square feet, and has an annual comprehensive production capacity of 1000 tons of aluminum alloy castings. Our customers come from more than 30 countries in the world. More and more people come to us and ask for cooperation. Our company has strong technical strength, a group of high-quality professional and technical personnel, with mold design, product development, product processing and other capabilities. There are 103 engineering technicians, including 6 engineers and 2 senior engineers. The company has more than 4700 casting molds, more than 80 CNC machine tools and machining centers.

Our company is an excellent supplier of SINOTRUK, which supplies 80% of its aluminum casting products. Among them, the radiator end tanks, cylinder block, valve body, engine parts, motorcycle parts and other series of products of the automobile intercooler are awarded the honorary titles of exempt products, excellent suppliers and reliable quality units by customers. Welcome customers at home and abroad to visit, investigate, invest and cooperate!

XD takes the “Quality Is Life” as production standard and principle,our products have enjoyed a good reputation for high quality among our customers. Sometimes, what they need is very simple–reliable quality, reasonable price, on-time delivery and good service, these are what we can supply. XD‘s vision is “To maximize the satisfaction of customers and employees, to be a top company in the industries in China”. Today, we are keeping pounding away at the expansion and development!

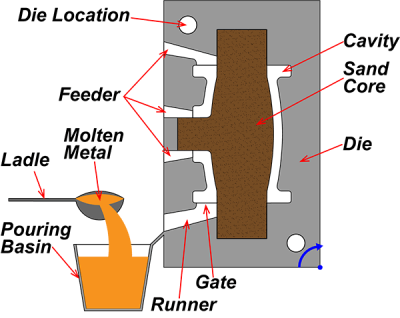

We are mental mold casting process. Depending on the mold, the process can be divided into manual mould casting and flip machine mould casting.

Manual mould casting

Manual mold casting, through artificial opening mold. The mold parts is less, so the mold price is lower; Due to the port is small, it can speed up the cooling, and the production efficiency is higher. Compared to sand casting, although belong to gravity casting, but in technology and economy, the mental mould casting has many advantages:

(1) the production's mechanical properties of metal mold casting is higher than sand casting. The same alloy, the tensile strength can be improved about 25% on average, yield strength increases by about 20% on average, its corrosion resistance and hardness also increased significantly;

(2)the casting surface precision is higher than sand mold casting, so as the quality and size stability;

(3)the liquid aluminum consumption can reduce 15-30%;

flip machine mould casting

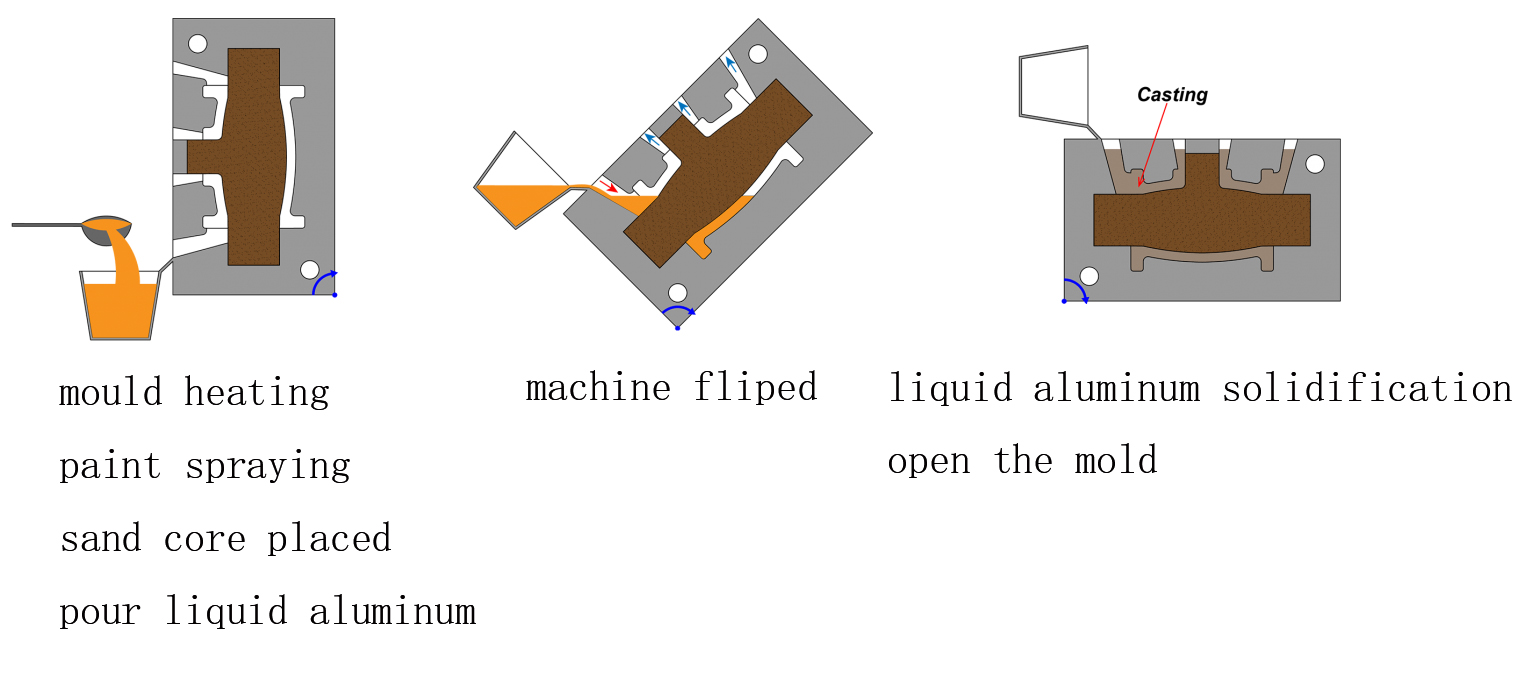

After liquid aluminum into the mold, the machine filp the mould , which can effectively eliminate gas inside the cavity and improve the efficiency of aluminum liquid filling, improve product quality. Use machine open the mould, it can reduce the working intensity, reduce product defects caused by poor working proficiency. Specific process is as follows: